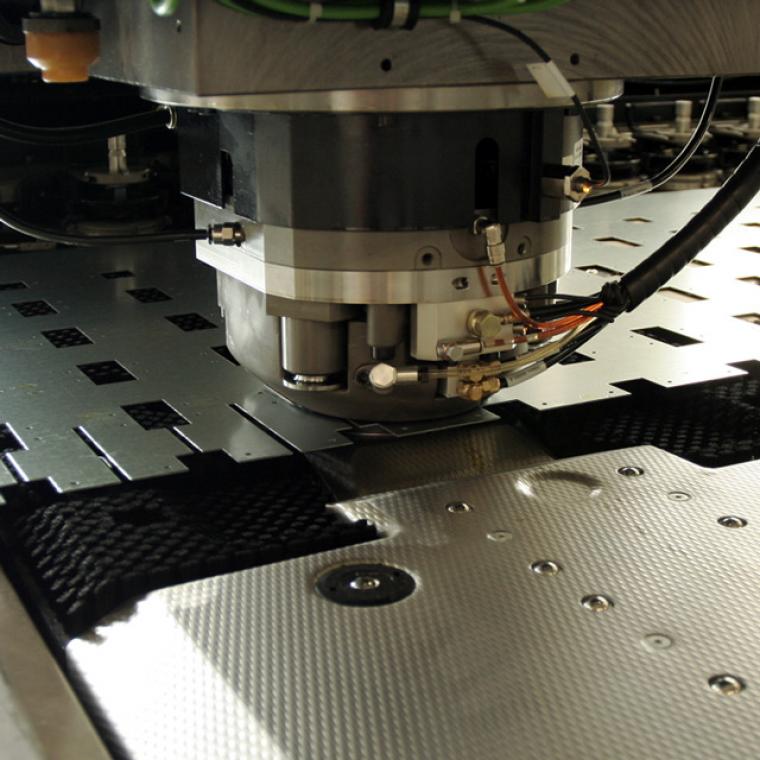

Laser

cutting is a technology used for cutting metal and industrial components with

various sizes and hardness. The technology guarantees precision and flexibility

and allows for a significant increase of the process' productivity.

The

laser beams do not affect the visible deformation of the metal and also allow

the obtaining of a minimal incision area with almost no deformation at the

edges.

The TruLaser 3030 fiber fiber laser machine used in Traktor Ltd. is fully automated with high operating speed and uncompromising quality. The machine has the ability to process larger thicknesses of structural steel, stainless steel and aluminum alloys. The laser cutting machine is equipped with two movable replaceable tables with dimensions 1500 x 3000 mm and is adapted for continuous three-shift mode. The maximum cutting thicknesses for the different materials are: